HYDROGEN IN BRICK PRODUCTION:

cH₂ange starts here.

Natural gas has carried us through the decades – now we bear a responsibility. The brick production industry is one of the most energy-intensive of all. So we need solutions, not excuses. Hydrogen is our answer to one simple question: what form will brick production take if we are serious about protecting the climate?

„

Why hydrogen? Because anything else would be standstill.

Dr. Caroline Foyer-Clitheroe

2045 CLIMATE TARGETS – BUT HOW?

With hydrogen.

And the right technology.

As a key element in decarbonisation, hydrogen puts us on the right course to achieving our climate targets by 2045. We are driving this complete switch forwards together with the Stadtnetze Münster and our partners supported with subsidies from the Federal Ministry for Economic Affairs and Energy and the EU.

EVERYTHING IS CHANGING HERE. APART FROM WHAT COUNTS:

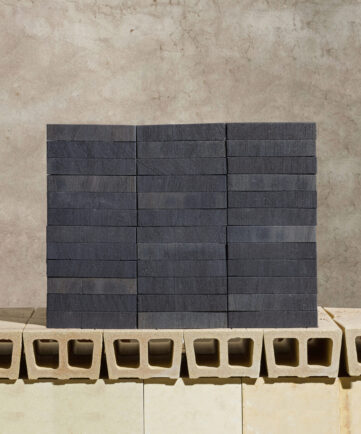

Quality. Variety. Durability.

Will the clinkers change due to the firing process using hydrogen? No. Even amidst the energy revolution, it is important to us that our clinkers retain their hallmarks: hard, durable, full of character. Just with less CO2.

We will continue to guarantee:

CLIMATE PROTECTION IS EXPENSIVE.

We are paying our dues – with resolve.

At present hydrogen is (still) vastly more expensive than natural gas. And yes – we are receiving a substantial subsidy from the Federal Ministry for Economic Affairs and Energy: a maximum of 62 million euros. That sounds a lot. And it is. But what many people don't know is that the subsidy only covers the difference in prices between natural gas and hydrogen and that it is paid out gradually. All of the other investments – infrastructure, conversion, process development – are being covered by us. Why are we doing this?

And that is precisely what we are doing. With resolve, as a family-owned business in the fourth generation.

The management of Janinhoff (from left: Hubertus Foyer, Ute Janinhoff-Foyer, Dr. Caroline Foyer-Clitheroe, Stephen Clitheroe)

Janinhoff Klinkermanufaktur

Thierstraße 130

48163 Münster-Hiltrup

follow us:

© 2025 Janinhoff GmbH & Co. KG